Tilt and slide PVC terrace door Softline PSK 70

Economy class tilt and slide PVC terrace door Softline PSK 70. Tilt and slide PVC terrace door PSK is the best choice for larger than medium or medium sized terrace doors.

VEKA Softline 70 PVC profile is of high quality, durable, features high heat retention parameters. These doors feature exceptional sealing properties and two opening positions. Due to its particular sealing properties, this door is ideal for buildings in severe climate zones, as well as terraces located in close proximity to sea.

U = 1,1 W/m2K (glass unit with 3 glass panes)

It provides an economic solution for buildings that don’t require the highest heat retention parameters (e.g., replacement for old windows). However, it should be noted that even as an economy version they surpass thermal insulation parameters that are required by legislation of many European Union member states.

Class A according to DIN EN 12608 quality standard. PVC terrace door PSK provides easy access to the terrace, possibility to enjoy beautiful surroundings, move easily between indoor and terrace areas, and easily ventilate the room.

Raw materials used for production of the window have been duly certified.

Application: residential and commercial buildings.

Frame thickness: 70 mm

Leaf thickness: 70 mm

Outside walls of PVC profile are 3.0 mm thick. The profile meets the highest quality standards and is rated as Class A.

The chambers are arranged in 5 rows.

Steel reinforcement is 1.5 mm thick or more.

Min: 1900 mm x 1900 mm

Max: 2360 mm x 4000 mm

Firm structure of the terrace doors allows production of article of unconventional dimensions. They must be separately coordinated for each unique design.

Tilt and slide PVC terrace doors.

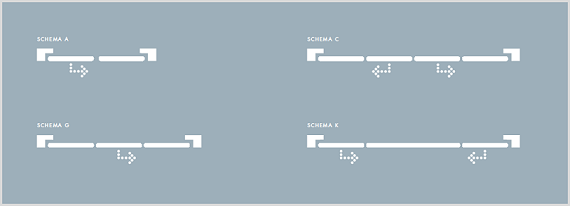

Structure of opening and non-opening sections of the terrace door is optional depending on individual requirements of specific project:

1. One section opening, another section – non-opening

2. Middle sections – opening, side sections – non-opening

3. One middle section – opening, side sections – non-opening

4. Side sections – opening, middle sections – non-opening

34 (-1;-4) dB (the value may slightly vary for products of different sizes)

The special sound-proofing glazed unit allows reaching 50 dB values.

Windows from VEKA AG profiles are rated to the highest class of protection against noise.

Solutions of window systems chosen for the project guarantee safety:

Protection against housebreaking and injuries

Standard option: indoor handle only – no possibilities to open the terrace door from the outside.

Terrace door must be fitted with safety glass unit, either laminated (protection against housebreaking and injuries) or tempered (protection against housebreaking).

Safety to health

All VEKA plastic profiles include only calcium-zinc stabilizers and are lead-free.

Highly appealing PVC terrace door of medium or large dimensions. Modern design of the PVC terrace door perfectly suits classic and modern interior. PVC terrace doors bring more light and cosiness to home.

Shapes

These PVC terrace doors may come in fairly large dimensions without any glazing bars, and as result bring lots of light and aesthetics to the interior. This is the right choice of terrace doors, as non-opening sections may be selected and arranged according to specific preferences.

Coating and colours

The VEKA Softline 70 profile has a classical design and superb quality of its surface and colour.

The colours can be selected from a wide range of standard and unconventional colours. The colours range from white to very dark; other possibilities include various colour shades, wood imitations, different colours on inside and outside.

Terrace doors may be fitted with a glass unit made of two or three glass panes.

Basic requirements to PVC terrace door

Safety glass panes must be used for terrace doors: protection against housebreaking and injuries is provided by laminated glass panes.

If it is necessary to simplify the structure of the PVC terrace door, it is important to make sure that at least tempered glass is used for protection against injuries.

High quality glazing seal is resistant to UV radiation, cold and heat, is stable and absorbs permissible fluctuations due to temperature changes.

Glass unit with two glass panes U = 1.1 W/m2K

(2 glass panes: 1 glass pane provide thermal insulation, filler – inert gas).

Light conductivity 79 %

Total solar energy conductivity 61 %

Glass unit properties:

1. Thermal glazing

2. Solar energy controlling glass units

3. Sound insulating glass units. It is possible to make it up to 50 dB by fitting thicker or special laminated sound-insulating glass panes.

4. Safety glass units

5. Decorative glass units

6. Fire-resistant glass units

7. ANTIFOG glass units

8. Glass units using atmospheric effect to keep windows clean (BIOCLEAN).

Standard – 24-40 mm wide glass unit

Ventilation is available by tilting the leaf of the PVC terrace door. Air vent can be fitted on the top of the glass unit as an option.

Note: Consult the manufacturer of windows concerning installation of vents to minimize heat losses.

Siegenia Aubi (Germany)

PSK PORTAL 160PLUS or PSK PORTAL 200-ZPLUS

Standard option: interior handle, small exterior pull handle.

Option with extra function: lock fitted inside and outside the handle, in the leaf. This option enables locking/unlocking the terrace door both from the inside and from the outside.

PVC windows with CE mark

PVC windows and doors meet the requirements of Construction Products Directive (EU). The basis of conformity declaration comes from ift Rosenheim GmbH.

Quality control according to requirements of RAL quality mark for Class A of PVC windows.

Thermal insulation according to DIN 4108 and EnEV, i.e., German energy-saving standards.

Sumeda UAB has implemented management standards ISO 9001, ISO 14001, and ISO 45001.

Sumeda UAB is certified at the Ministry of Environment of the Republic of Lithuanian.

Glass unit certificates

Implemented ISO 9001 system, DS certification, products comply with DS/EN 1279.1 requirements.

Hardware certificates

Siegenia-Aubi (Germany) hardware are in line with company’s Quality Management ISO 9001 certification, the companies focus on quality is reflected in an expanding product range that meets – and often exceeds – the reputation of “Made in Germany” standard.

The product is 100% recyclable.

Windows and doors are completely safe to health, since materials used for manufacturing meet the strictest EU norms for health safety, safety of use and environment protection.

PVC windows from VEKA AG profiles are especially firm.

They are marked as Class A for its strength and durability.

The profile is reinforced with a square steel tube of 1.5 mm thickness. This reinforcement ensures the maximal possible strength. Walls of PVC profile are thick. These features make the profile exceptionally firm.

1.5 mm thick reinforcement is sufficient according to window quality standards. However, in some cases we use 1.75 mm reinforcement to meet our internal quality standards, for example, in case of coloured products that are more affected by sunlight than white products.

Outside walls of PVC profile are 3.0 mm thick.

It is important to note that only original raw materials and no recycled materials are used for production of Class A products. All these features increase strength and quality of windows and doors.

The opening leaf is reinforced with a double-bent edge to achieve maximal strength.

All materials used in production of windows are certified, tested and durable.

Durability of plastic

VEKA AG produces PVC profiles only from unprocessed plastic. This ensures strength and durability of plastic and its resistance to deformations.

The primary difference that makes PVC window profiles from VEKA AG superior is the number of calibration points in the PVC profile manufacturing cycle. The said calibration practice make all VEKA AG products especially stable and resistant to mechanical and thermal impacts in the subsequent stages of manufacturing and ensures that the end product has not altered and is exactly what it was meant to be.

Durability of coating

Both white and coloured VEKA profiles are made exclusively in factory. It should be noted that the coloured profiles are always produced exclusively in VEKA AG factories; thus the colour coating is made “in-factory” during manufacturing of the profile itself, which guarantees superb durability of its surface and colour.

Only UV resistant stabilisers are used for profile production, therefore your windows and doors always remain UV resistant and will never fade in sunlight.

Durability of profile structure

The sealing bands are put in place during profile production only after welding of profile corners. For this reason, the sealing is not affected by welding heat along the whole perimeter, including the corners, and remains flexible, functional, and tight.

The seals are not welded, so they can be readily replaced.

Durability of glazing unit

Windows and doors are durable because of hermetic glazing units that are mounted in the products by means of completely water tight sealing.

Durability of fittings

Windows and doors are durable because of German-made fittings that are properly spaced, effectively distribute loads, and maintain their functionality.

Technology of VEKA AG is one of the oldest in PVC window market.

PVC profile with steal reinforcement is a time-tested combination that keeps exclusive strength and effectively retains heat at the same time. Vast experience of VEKA AG demonstrated that the steel reinforcement does not have a significant impact on thermal properties of doors and windows. Products based on this technology measure up to passive house windows.

From the start of PVC window production, we chose VEKA AG as our long-term partner. Over the years VEKA AG has proofed its reliability and high value of its profiles.

VEKA profiles enable us to offer professional PVC window systems. Design and manufacturing phases of your window systems will benefit from manufacturing and installation know-how accumulated by both VEKA AG and us. Our long term partnership with VEKA AG ensures smooth operations and high standards of production – deep knowledge of the profile and excellent quality of products.

PVC windows and doors require minimal maintenance.

Here are the main instructions to remember:

– Do not use aggressive surface cleaners for PVC products.

– Make to sure to protect PVC windows and doors from construction materials, since they can cause irreparable damage if they get on the product surface. Note: Do not use aggressive sticky tapes that may damage the surfaces.

– Immediately remove the protective film after installation works have been completed since it can cause surface damage if left in place for a longer period.

– Remove dirt and dust from the surfaces several times a year. Use water-damped sponge or cloth. PVC profiles may be cleaned with soapy water or water and soda.

To properly use windows and doors the following factors must be taken into account:

– Proper transportation and storage of production

– Protection and care of profile surface

– Care of glazed units

– Maintenance of sealing and drainage openings (especially after construction works – do not leave debris inside)

– Maintenance of opening mechanism (especially after construction works – do not leave debris inside, oil the opening mechanism twice per year)

– Proper ventilation